The main drafting unit of China’s national tire valves standards

Deputy Director of Tire Valves Committee, China Chemical Industry Association

Deputy Committee of Tire Valves Technical Committee, National Tire & Rim Standardization Technical Committee

Member of European Tire & Rim Technical Organization and American Tire Industry Association

A major manufacturer of valves and TPMS globally.

.png)

.png)

.png)

.png)

Intelligent products

Differentiated

functional modules

and solutions

Intellisense

Multi-sensor fusion

Planning control

Business model

Delivery pattern

Strategic collaboration

20 years' experience in auto electronics

Strategic partner of main chip manufacturers at home and abroad.

chip vendor

High-end manufacturing

capability

TM

TM

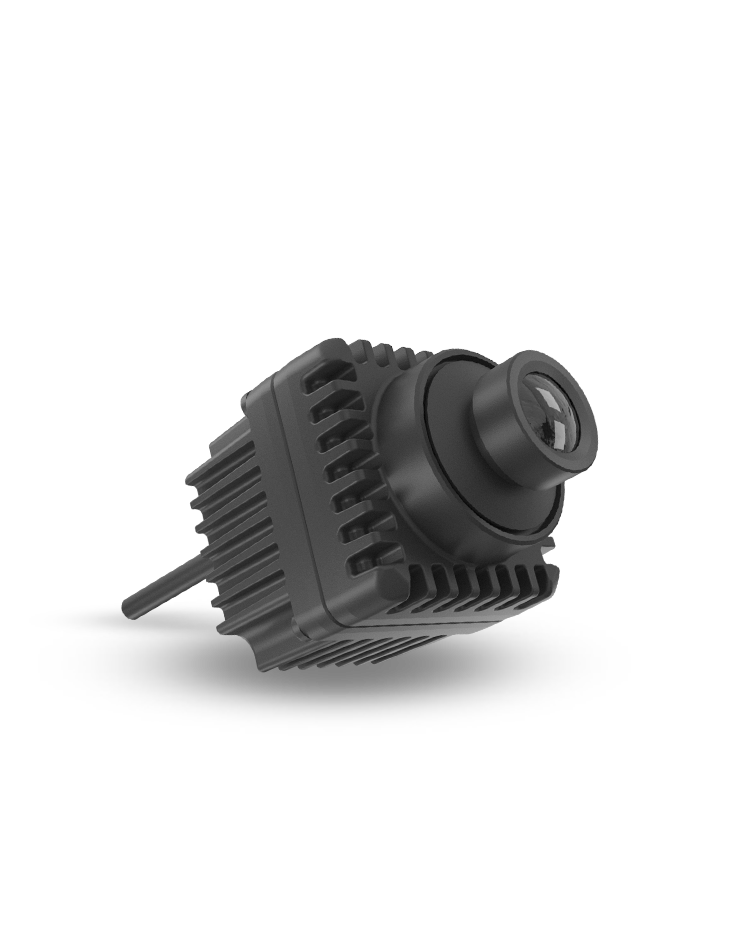

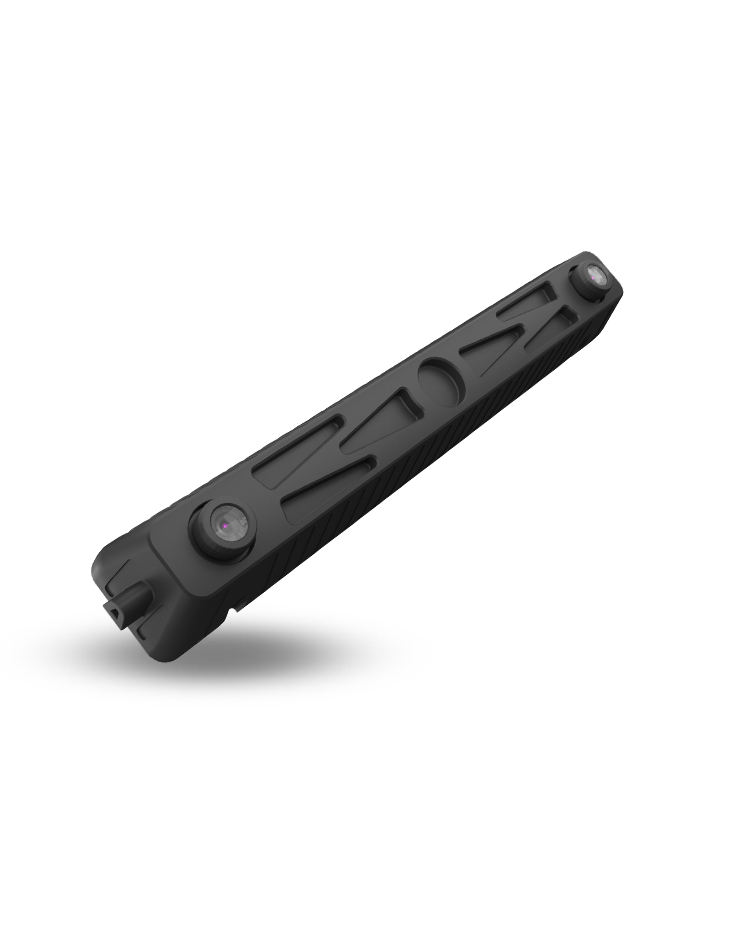

High speed: Baolong provides front cameras and solutions for cockpit system with independent intellectual property rights. The front cameras include monocular camera and stereo camera, with image perception of 1M to 8M pixels. The cockpit system includes DMS, OMS and face ID, to realize monitoring, identification, alarm, interaction, etc. In addition, the company develops and manufactures various camera module products.

Low speed: the company can customize and develop software algorithm system of AVM and fusion of parking based on cockpit domain and domain controller, and camera modules of various pixels (1M, 2M, 3M, 8M) and FOVs. It supports independent AVM controller, controller for fusion of parking, integration of DVR, delivery upon white box testing and platform customization.

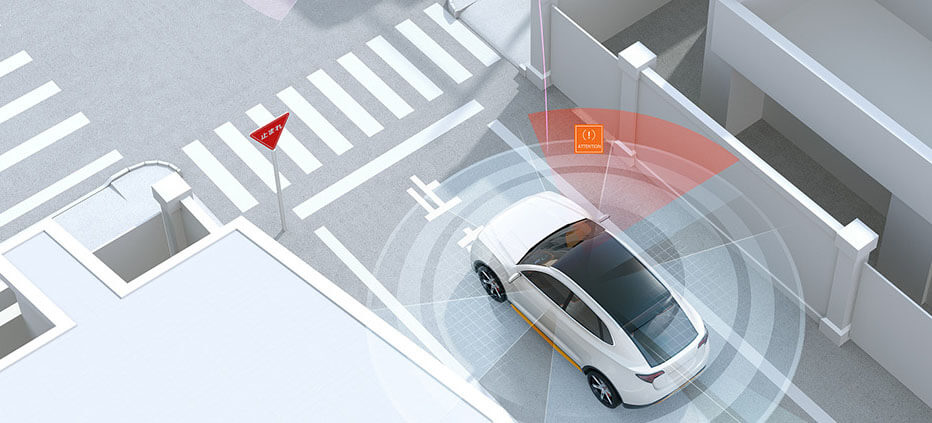

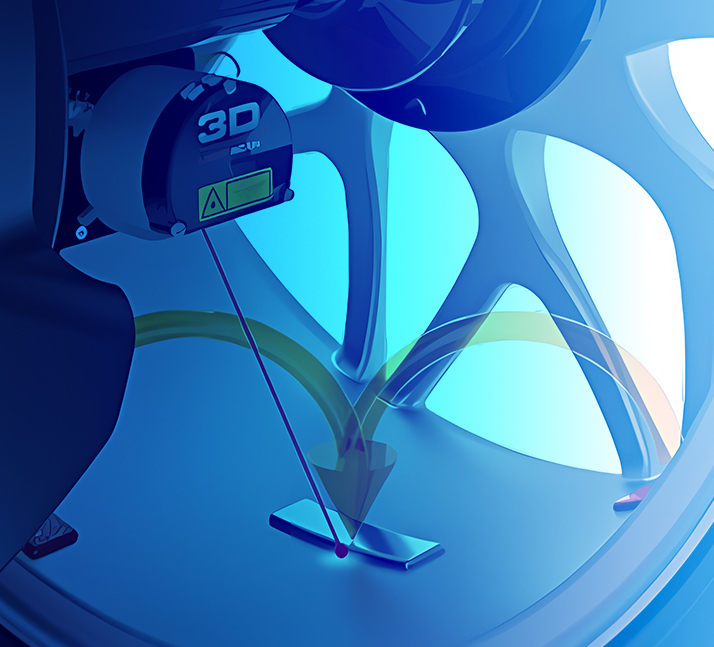

Involved in millimeter-wave radar for many years, Baolong possesses independent intellectual property rights in software and hardware, algorithms, antenna design, etc. With a complete development process system and advanced automated production line, it provides customers with high-quality radar to ensure driving safety.

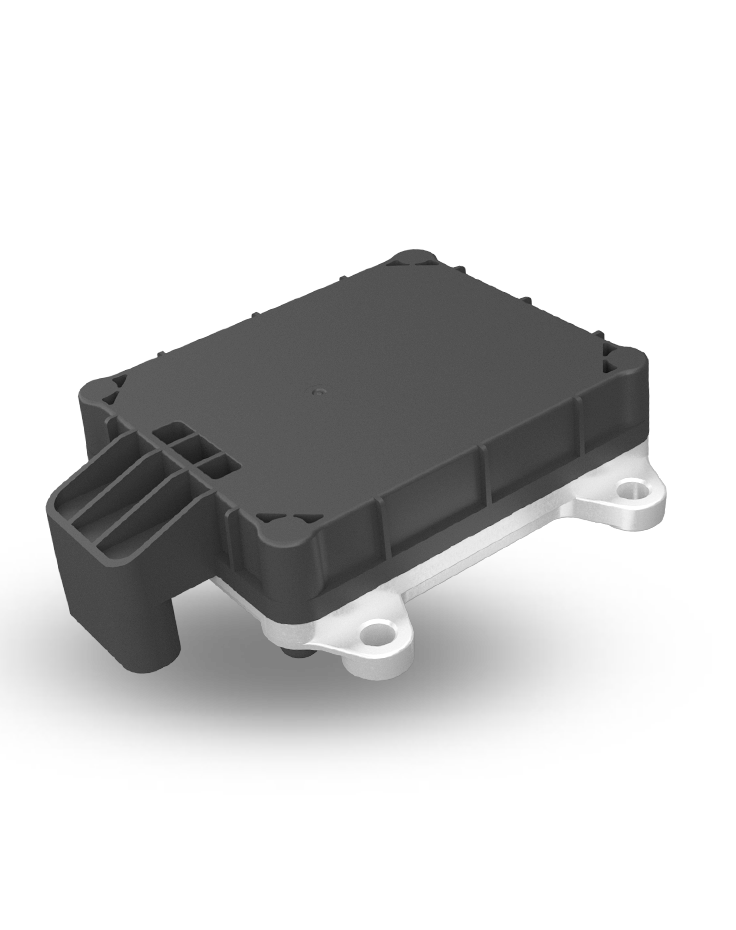

For high-level automated driving applications, the company provides a series of domain controllers that support integration of driving and parking, which are compatible with a variety of mainstream (AI) SoC chips, with computing power of 8~100+Tops, and realize functions of HWA / HWP, TJA / TJP, APA / RPA/AVP.

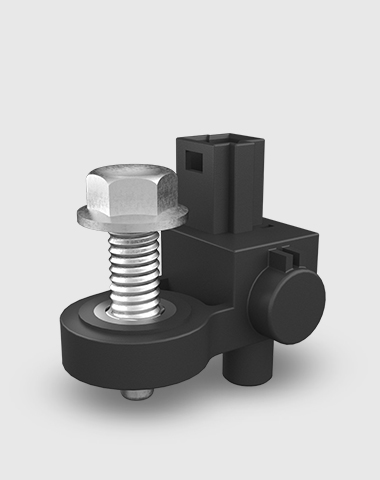

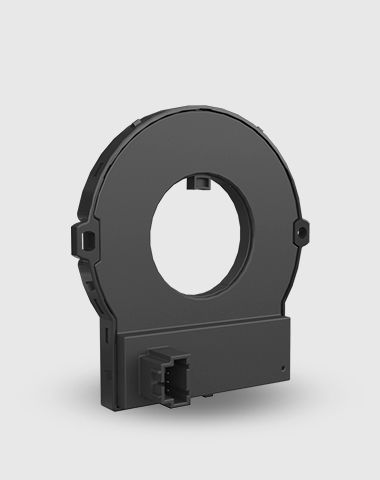

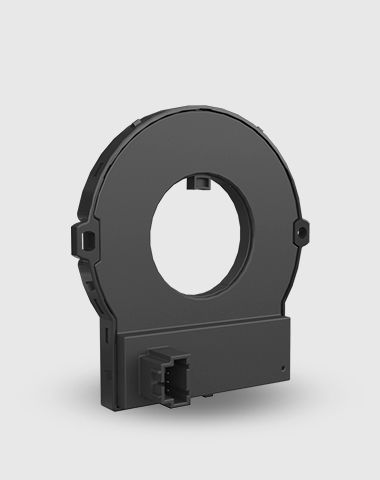

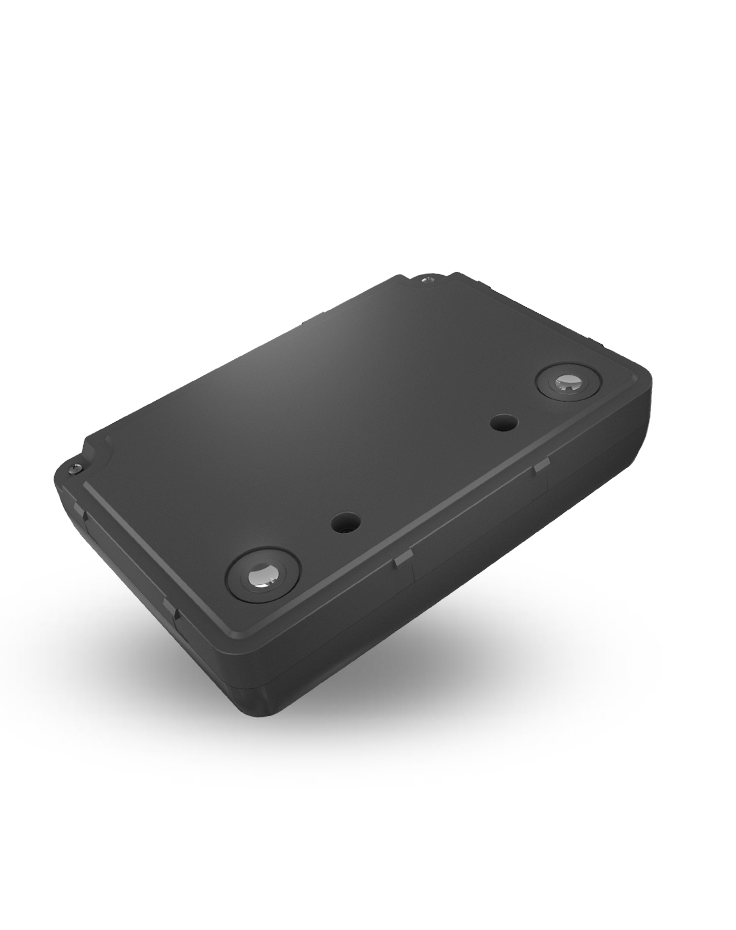

The ultrasonic sensor system designed and developed by Baolong can realize position detection and coordinate detection of obstacles near the vehicle. It supports detection distance of 3M, 5M, and 7M. By matching the installation position of sensors and optimizing the software filtering algorithm, the detection of low obstacles can be realized while avoiding false alarms on the road. Based on this, the ultrasonic sensor system can realize ADAS functions such as parking assist warning (PAS), automated parking (including integrated automated parking and remote parking), blind spot detection (BSD) of rear side, emergency braking at low speed (MTG), etc

We will use Cookies to optimize your browsing experience and implement website functions through third-party SDKs, If you wish to continue browsing this website, please agree to the use of Cookies and the Privacy Policy